In the production equipment of medical equipment, bonding technology is often used, and UV glue is widely used.

Although the process is simple, consistent and repeatable bonding will be formed in the production process. At this

time, in order to improve efficiency and ensure high quality of products, uvled light curing technology is particularly

important.

UVLED light curing technology refers to the process of applying uv glue or uv ink to the surface of the product,

and irradiating the surface of the object with ultraviolet light emitted by the uvled curing machine, thereby curing

the glue or ink. So why use uvled light curing technology in the production and assembly of medical devices? What

advantages does uvled light curing technology have in medical device assembly?

1. Fast curing speed can effectively improve production efficiency;

2, the temperature rise is small, to avoid the impact of high temperature on the quality of medical equipment;

3. The equipment is small in size and easy to operate;

4, can adjust the intensity of light irradiation, improve the effective utilization of energy, save energy;

5, can be customized according to the size of the product suitable light source.

The following are examples of UVLED curing in medical applications:

(1) Hearing aids;

(2) endoscope;

(3) a syringe;

(4) intravenous infusion tube;

(5) Anesthesia mask;

(6) Catheter;

(7) Arterial positioning;

(8) Detection, monitoring, and imaging equipment;

(9) blood oxygenator;

(10) Vascular implantation accessories;

(11) Biochip;

(12) tubular drainage device;

(13) Tracheal pipes;

(14) Bonding PVC, thermoplastics (polycarbonate and ABS).

UVLED light curing technology has a significant role and significance in the assembly of medical devices.

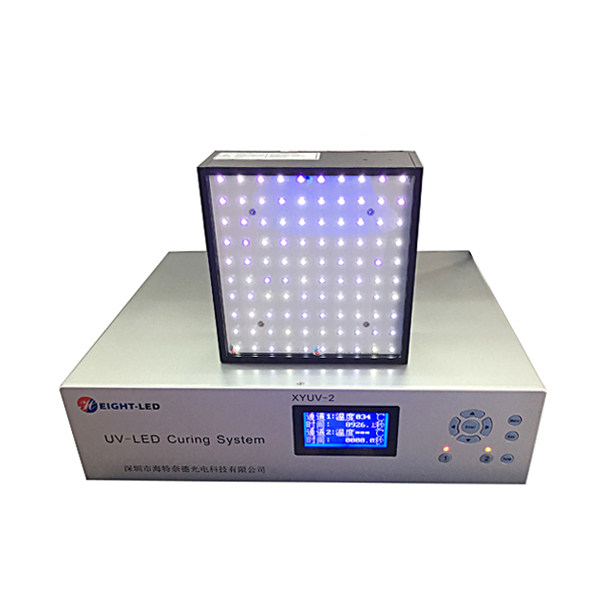

Shenzhen Height-LED specializes in the production of uvled light sources and curing equipment. The products are

widely used, with high quality and can be customized. Welcome to consult!