The development trend of UVLED has been overwhelming. More and more manufacturers have put uvled light curing

machines into use. Then,how to purchase uvled light curing machines? What factors need to be considered when buying?

The editor summarized several aspects,hoping to help manufacturers who want to buy uvled light curing machines.

1.Chip selection

The light source is best to use imported chips, vacuum inorganic material packaging, light attenuation is smaller,

stability will be better.

2.Cooling method

The cooling method is best to use water cooling to dissipate heat. The LED temperature will be low, so the service

life of UV LED will be longer.

3.UVLED energy

Precise control of UVLED intensity and exposure time enables precise control of UVLED energy. For the control of

exposure time, our advanced UVLED curing machine, built-in computer microprocessor, can set the exposure time and

various modes.

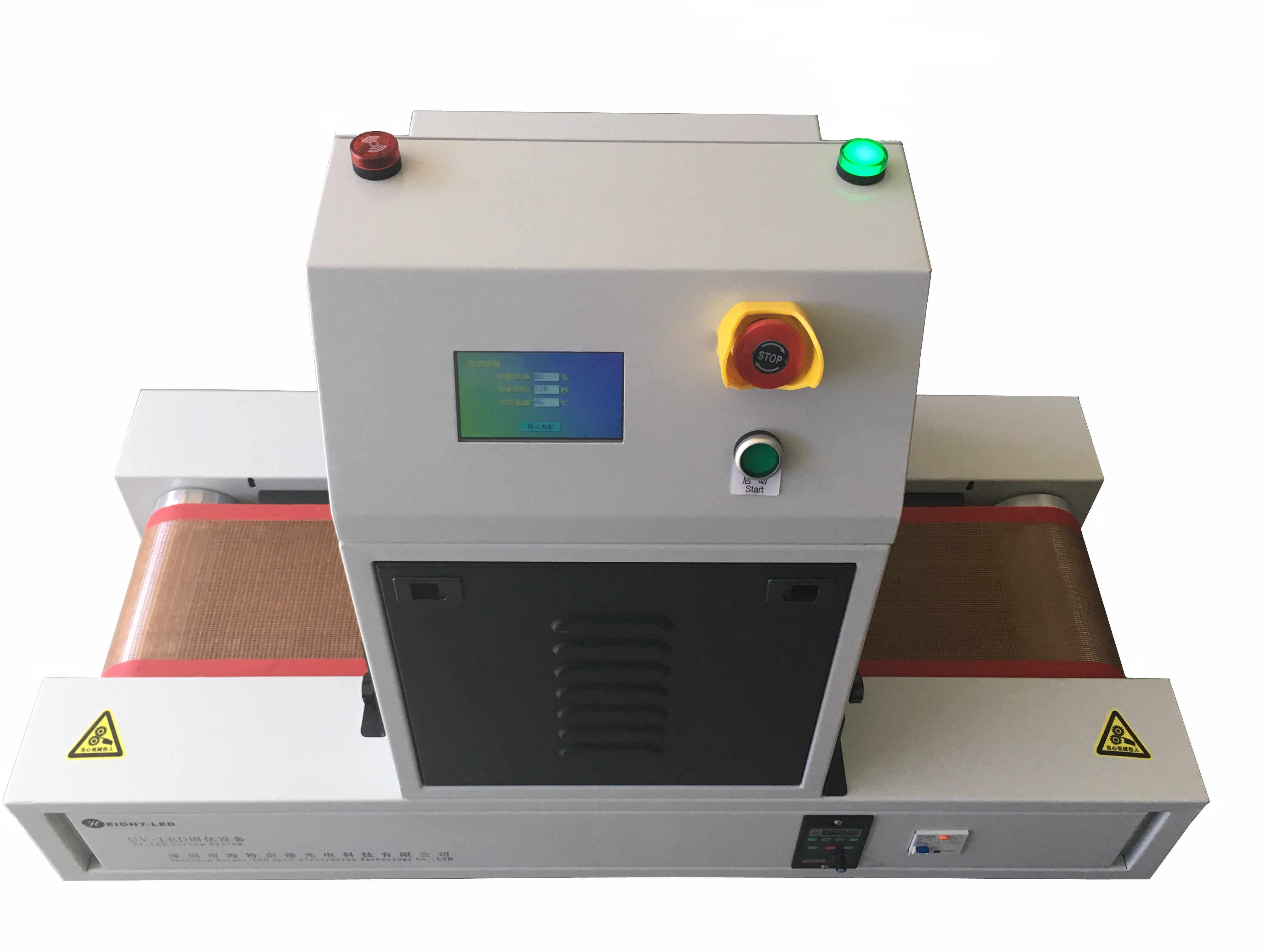

4.Strength of UVLED curing machine

Generally speaking, the UV intensity of the UVLED curing machine is very uniform, and the wavelength range is about

300nm-400nm.Do not choose some so-called UVLED curing machines that have no data at all.

5.UVLED spectrum

At present, due to the development of light curing, many applications have appeared, such as surface curing, visible

light curing,etc.There are also some UVA, UVB or visible light enhanced bulbs. Advanced UV dryers can generally be

equipped with different spectrums without any hardware changes. This can greatly increase the flexibility of research

and development.

6.UVLED curing machine safety and temperature

Advanced UVLED curing machine with lock security, automatically closes the exposure shutter to protect user safety.

Other designs, including cutting-edge thermal chip technology and computer microprocessor functions, effectively control

temperature rise. This point requires special attention. Traditional mercury lamps do not have a well-controlled light

source, which can cause serious hidden dangers of bulb burst.

7.UVLED light source stability and reliability

This point is difficult to directly prove with traditional craftsmanship, which is generally the accumulation of industrial

experience. Generally, laboratories are not equipped with machines, and an unstable light source seriously affects the relevant

test progress.

When choosing a good uvled light curing machine, the most important thing is to see what industry needs to be used and

what characteristics of the product to be cured. Choose a uvled light curing machine according to your product. Do not

compare the light source parameters, because in different fields,different products have different requirements. Shenzhen

Height-LED is a professional supplier of uvled curing equipment and solutions, which can accept customization and sincerely

solve curing requirements for customers.