The development of technology has brought convenience to the production of the industry. The emergence of UVLED curing oven has improved the efficiency of product curing for large enterprises and also increased the quality of product curing. At present, UV curing technology has been widely used in the world. Glue and ink curing all use UVLED curing mode, which has become the mainstream choice for enterprise development.

Why does the market choose UVLED curing oven as an alternative to traditional curing mode?

Because the UVLED curing furnace does not use the same mercury lamp as the traditional one in the design process, because the traditional mercury lamp has high brightness and generates a lot of heat, the product may be affected by the external temperature during the curing process. change. The UVLED curing furnace uses a cold light source, which is relatively concentrated and has a high conversion rate. The temperature of the material surface is low during curing, so the scope of application is wider.

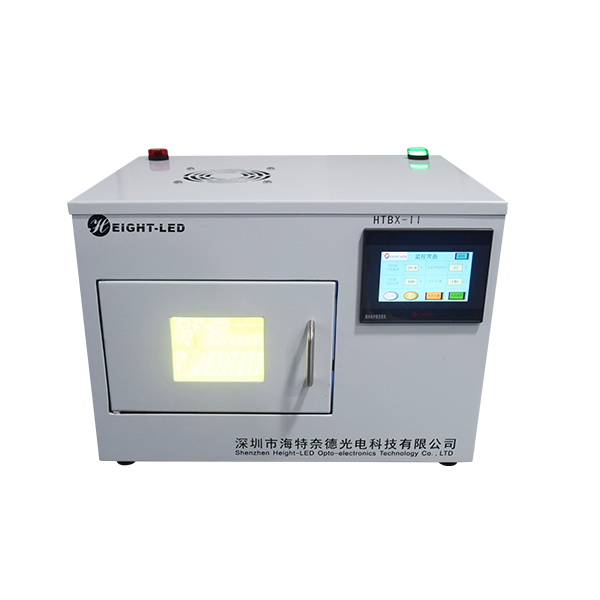

The second is that the UVLED curing furnace has a long life during use, and it works by touching the display. There is no need to wait, and the light can be directly turned on to save energy and reduce the loss of the machine itself.

Compared with the traditional mercury lamp, the UVLED curing furnace emits light through the chip on the ultraviolet diode, and the electric energy is converted into light energy without any polluting gas or liquid generated, so it is better than the traditional one. Mercury lamps are more environmentally friendly and pollution-free.

The advantages of the product will be compared with the traditional mode, so that customers can know at a glance why the UVLED curing oven is used as the main curing equipment in the market, because it has better use effect.

As a manufacturer of UVLED curing equipment, Shenzhen Height-LED is committed to providing customers with a complete set of curing solutions. The products have standard products and can also customize products according to customer needs. If you have UVLED curing requirements, you can contact online customer service, or call for consultation and exchange.