In the past, mercury lamp irradiation was used in many industries. The equipment of this irradiation method also has many disadvantages, such as high maintenance cost, fast attenuation of UV light irradiation, surface temperature increase on the surface of the irradiated element, large volume, Expensive consumables, mercury pollution, etc. After the emergence of UVLED curing machine, this irradiation method was gradually replaced.

Since the birth of UVLED curing machine, it has achieved revolutionary changes in the curing industry. This curing technology has more advantages, such as stable irradiation intensity, good temperature control, energy saving and environmental protection characteristics. At the same time, the service life of the UVLED curing machine will be higher. The service life of the traditional mercury lamp is up to 3,000 hours, but the service life of the curing machine is as high as 20,000 hours. It can be seen that the service life will be longer, and in actual use China has indeed shown a greater advantage. Moreover, the lifespan of LEDs is more than 10 times that of mercury lamps, reducing the investment cost of equipment. It can be turned on and off immediately, without preheating, and the number of times of switching does not affect the service life.

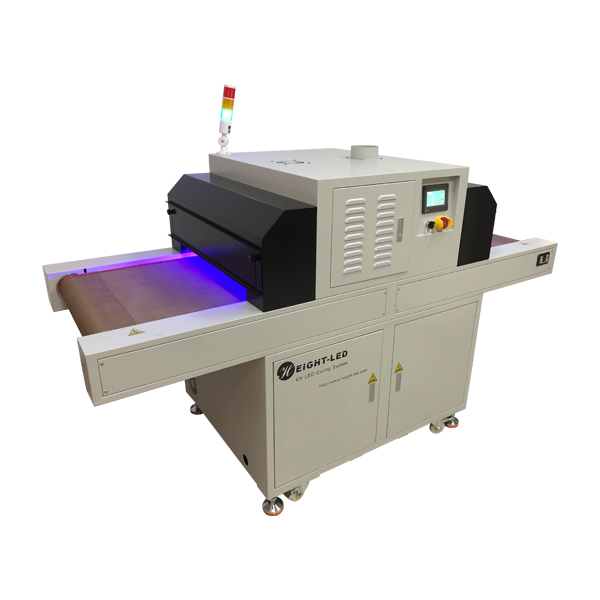

Therefore, the choice of UVLED curing machine not only improves the production efficiency, but also realizes the needs of energy saving and environmental protection. As a manufacturer of UVLED curing equipment, Shenzhen Height-LED is committed to providing customers with a complete set of curing solutions. The products have standard products and can also customize products according to customer needs. If you have UVLED curing requirements, you can contact online customer service, or call for consultation and exchange.