Basically all UV-sensitive materials available on the market can be cured with a UVLED curing oven, including photosensitive resins in 3D printing. The printed material of the photosensitive resin is very thin and will be soft after being placed for a while. At this time, a UVLED curing oven is required for secondary curing. Normally, the higher the light power, the better the curing effect.

However, in practical applications, is it true that the greater the power of the UVLED curing oven, the better the curing effect, and the faster the curing speed? In fact, it is necessary to choose a UVLED curing oven with the appropriate wavelength and power according to the characteristics of different photosensitive materials. For the specific choice, you should consult the photosensitive resin manufacturer and the UVLED curing oven manufacturer, and determine the purchase after comprehensive consideration and testing.

The power of the UVLED curing oven is the UVLED radiation energy, also known as the penetration. First, it must meet the requirements of the spectral wavelength and power density absorbed by the UV ink (varnish). If the power of the UVLED curing oven is not enough, no matter how long the light is, no matter how many times the UV curing device is passed, the product will not be fully cured. On the contrary, it will also make the surface layer of UV ink (varnish) aging, become brittle, etc. At the same time, the adhesion of the ink (varnish) is not good, which will make the interlayer bonding of the overprint poor. Because the low-power UV curing lamp cannot penetrate the bottom of the ink layer, the bottom is not cured or cured insufficiently.

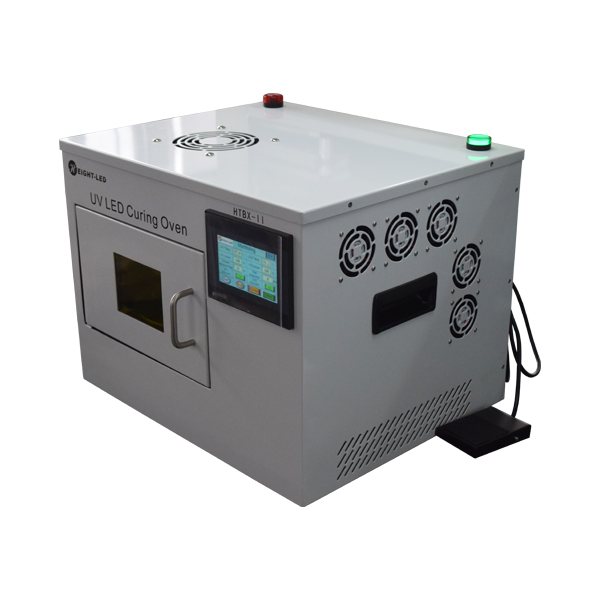

In this case, the advantages of UVLED curing oven compared with UV mercury lamp are obvious. The greater the power of the UV mercury lamp, the greater the heat, and the mercury lamp needs to be replaced every 800-1000 hours, which is not friendly to heat-sensitive materials and delays production efficiency. Height-LED UVLED curing oven has a good heat dissipation design as a cold light, even if it is operated for a long time with high power, the temperature rise of the equipment will not be very high, and there is no need to replace the lamp beads. Therefore, as long as you communicate the wavelength required for curing with the photosensitive material manufacturer, the UVLED curing oven can complete the curing very well. Of course, the higher the power of the UVLED curing oven, the better the effect. A good curing requires a combination of power, wavelength, irradiation distance, irradiation time and other factors to achieve a better curing effect in the end.

Shenzhen Height-LED specializes in the production and sales of UVLED point light sources, UVLED line light sources, UVLED surface light sources, UVLED curing machines, UVLED curing ovens, dispensing, spraying, spraying, automation equipment and other products. It has a professional team and rich experience. Suitable UVLED curing system can be customized for customers, welcome to consult.