Next, I will introduce the knowledge about the UV curing machine for film printing.

Film printing is also divided into several types, including high temperature resistant and non-high temperature resistant. The high temperature resistant can be cured with high temperature radiation within the allowable temperature range. The printing of the plastic film that is not resistant to high temperature is performed before the UVLED cold light source comes out, and the temperature and time constraints should be considered for the radiation curing. The printing process is also strict. The printing substrate of the film is distinguished from the material, which can be divided into plastic and metal, and plastic is mostly used. The printing UV curing of metal film also has temperature limitations, because heating the metal film substrate at too high temperature will cause the cured UV coating to separate from the substrate. This is caused by temperature.

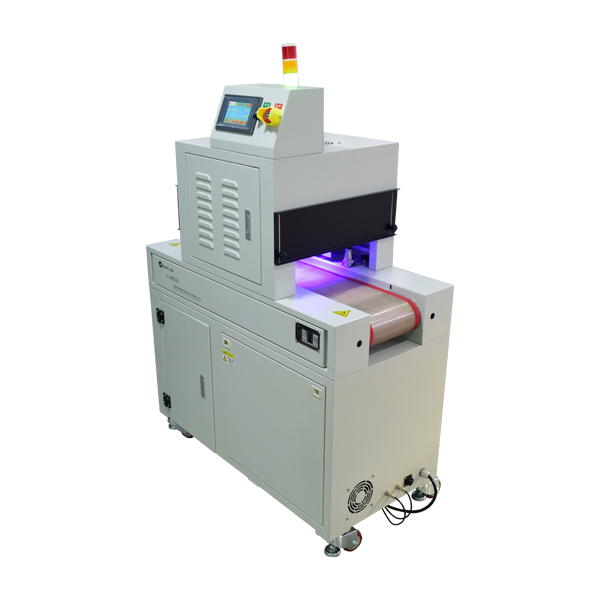

The reason why the film printing UV curing machine is a low-temperature cold light source is that the LED chip lamp bead is combined into a UVLED curing machine irradiation head that emits ultraviolet radiation light source. The LED chip emits a cold light source of ultraviolet radiation to irradiate and cure the substrate. The lamp bead itself does not generate heat, but the ultraviolet radiation itself has a certain temperature, and this temperature gradually increases as the irradiation time increases.

Generally, UV glue or UV ink of photoinitiator is used for printing and curing with film printing UVLED curing machine. As long as the bands are matched properly, a few seconds is enough to cure the UV layer.

If you also have film printing curing needs, you can contact us through online customer service, website message, call, email, etc. Height-LED will provide a satisfactory and suitable UVLED curing solution for your curing needs!