UVLED is a new technology that emits ultraviolet light through semiconductors. At present, the most mature waveband is mainly in the UVA waveband. The cost of other bands is still very high and has not reached the stage of widespread application.

UV curing is a photochemical reaction, that is, the liquid UV curable material is printed or coated on the surface of the substrate or workpiece, and the curing process is realized by UV light. UV curing is similar to the traditional drying process, but the principle is different. The traditional Drying generally relies on the volatilization of the solvent in the coating material to form hardening, while the UV curing crosslinking has no solvent volatilization, which is environmentally friendly and economical, and the UV lamp has high efficiency.

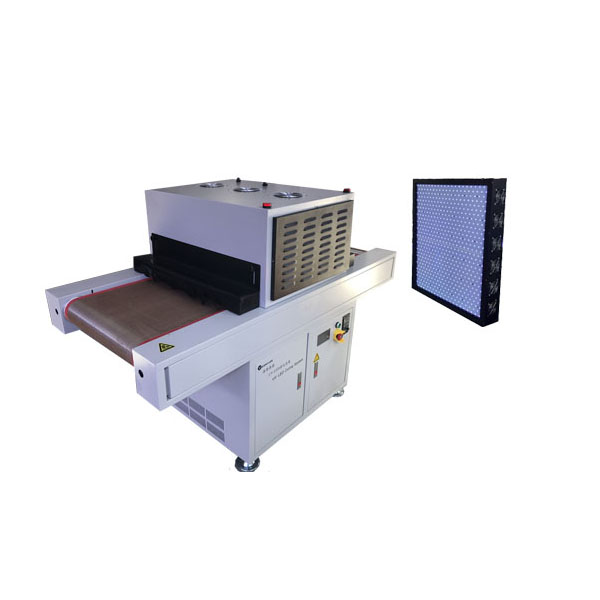

The UVLED curing machine is a curing system integrated with UVLED light-emitting technology through scientific heat dissipation design, optical processing design, intelligent control system and related structural design.

The surface curing currently applied on the market is mainly based on the 365nm and 395nm peak wavelength spectra. What kind of spectrum is needed to achieve the best effect depends on the glue or ink used, and can be known by consulting the glue or ink supplier. In addition, as the wavelength of UVLED is compared with traditional UV lamps, the wavelength of the spectrum requires a single UVLED curing machine. If you need to achieve a more ideal effect, it is best to ask your supplier when choosing UV glue and UV ink. Is there a model with a single wavelength UVLED light source?

The UV intensity of the UVLED dryer is very uniform, and the UV radiation intensity is considered when designing the product. For the curing light source, with imported high-power LED and high-tech optical lens, unique software control program, the irradiation intensity range is 1000mw/cm2-8600mw/cm2.

Advanced LED-UV curing machine with safety lock, air pressure alarm, no glue alarm, abnormal point self-diagnosis function to protect user safety. Take Height-LED curing equipment as an example, using cutting-edge heat dissipation chip technology and microprocessor functions to effectively control the temperature rise. This requires special attention. Traditional mercury lamps have a light source whose temperature is not well controlled, which can cause serious hazards of bulb bursting.

stability

It is difficult to directly prove this with traditional crafts, and it is generally the accumulation of industrial experience. General laboratories are usually not equipped with special machines, and an unstable light source seriously affects the related test progress. And we have rigorous field testing and years of R&D and design experience to ensure the stable use of the light source.

Shenzhen Height-LED specializes in the production and sales of UVLED point light sources, UVLED line light sources, UVLED surface light sources, UVLED curing machines, UVLED curing ovens, dispensing, spraying, spraying, automation equipment and other products. It has a professional team and rich experience. Won the title of National High-tech Enterprise. Welcome friends in need to come to consult.