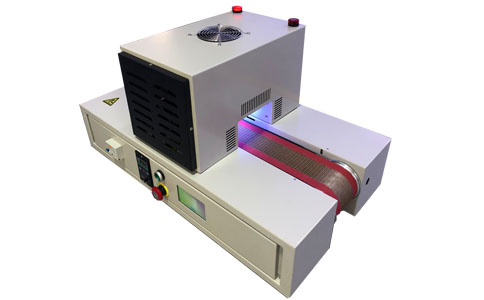

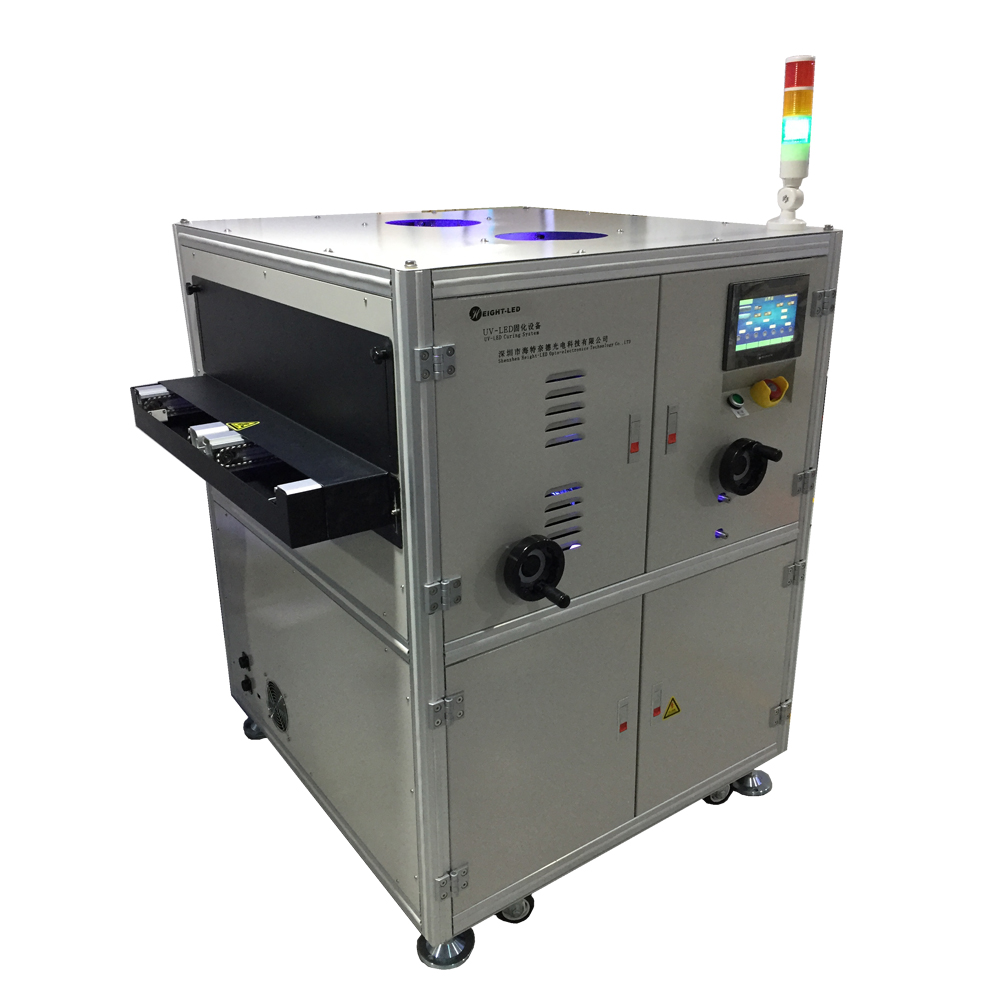

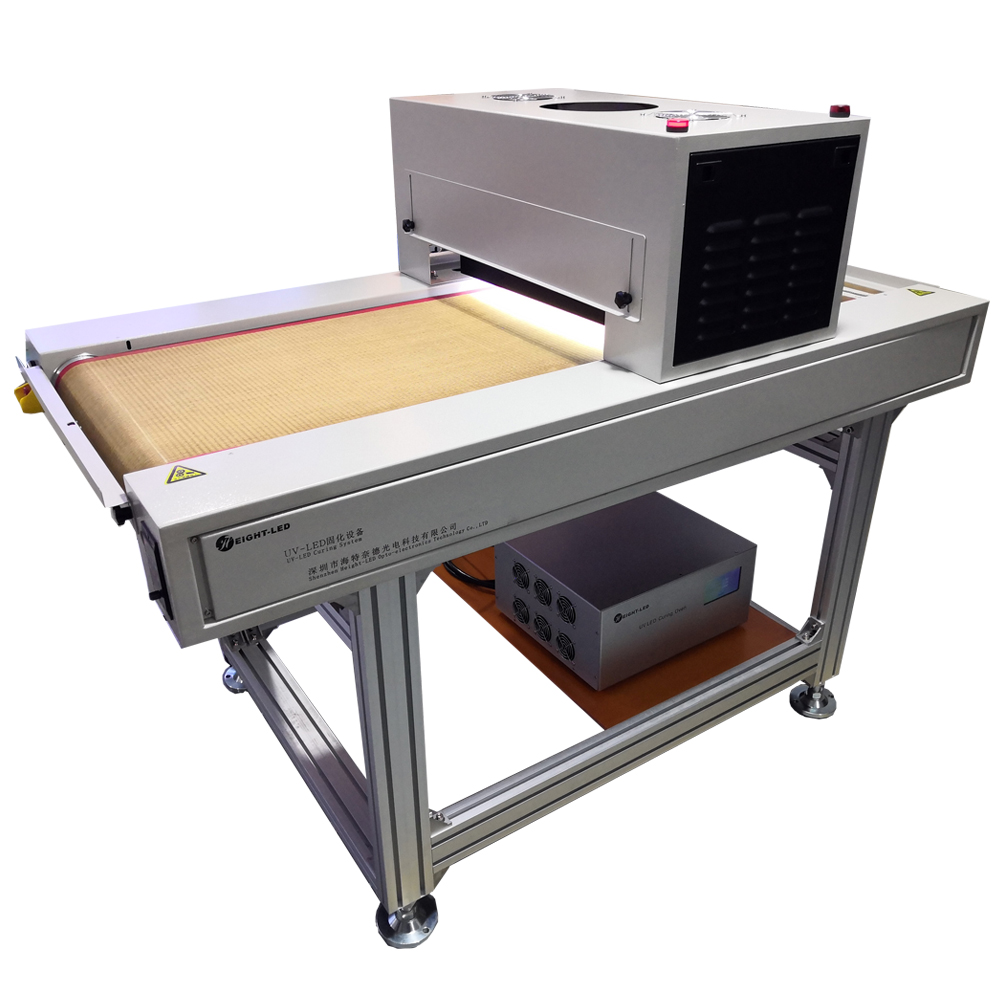

As a kind of curing equipment, UVLED curing machine has multiple advantages compared with traditional UV mercury lamps,

such as fast curing speed,environmental protection and safety, convenient operation, cold light source, etc. The curing

principle is that the photo-initiator is triggered after UV coating is irradiated by UVLED. Generating a ionic group or ion

that crosslinks with a double bond in a prepolymer or an unsaturated monomer to form a monomeric gene that initiates a chain

reaction to form a polymer solid away from the molecule, which It is a complete curing process. What I shared with you today

is the major factors affecting the deep light curing of UVLED.

First, the impact of UVLED energy

The deep curing of ultraviolet radiation, the main condition is that the molecule must absorb the photon with sufficient

energy to become the excitation molecule, decompose into free radicals or ions, and make the unsaturated organic compounds

undergo chemical reaction such as polymerization, grafting and cross-linking to achieve the purpose of curing. The energy

required is supplied by a photoinitiator in the UV coating, in two cases. When you do not know the UVLED cold light source

energy required by the photoinitiator, such as blind excess supply, this method not only wastes energy, but also causes negative

effects of excessive curing, such as explosion, anti-cure reaction, etc.; when the UVLED energy is insufficient The energy of

the UVLED must be moderate, that is, it should not be excessive or insufficient, so as not to cause complete curing.

Second, the impact of curing distance

The ultraviolet lamp generally has a distance of about 10-15 mm depending on the solidified substrate. The curing distance

must be properly adjusted with the irradiation power of the substrate, paint, and UVLED lamp.

Third, the impact of UV light curing speed

According to the difference of substrate, paint, curing distance, etc., the curing speed of the equipment is adjusted

appropriately. If the curing speed is too fast, the UV coating on the surface of the substrate is sticky or the surface is dry and

the inside is not dry; if the running speed is slow, the surface of the substrate will age.

Fourth, the impact of UV coating thickness

The thickness of the UV coating plays a key role in the effect of UV curing. The coating is too thick and the drying time is

relatively long under the illumination of the same power source. On the one hand, it affects the drying of the UV coating, and

on the other hand, the surface temperature of thesubstrate. Too high, causing deformation of the substrate; too thin coating

will result in poor gloss on the surface of the product. The UV coating of the thick coating should be properly formulated under

different conditions such as hue, temperature, curing speed, and substrate surface.

Fifth, the impact of the working environment

When the viscosity of the UV coating changes greatly due to temperature, the room temperature should be adjusted.

Generally,15-25 °C is suitable, and the curing should not be exposed to direct sunlight.