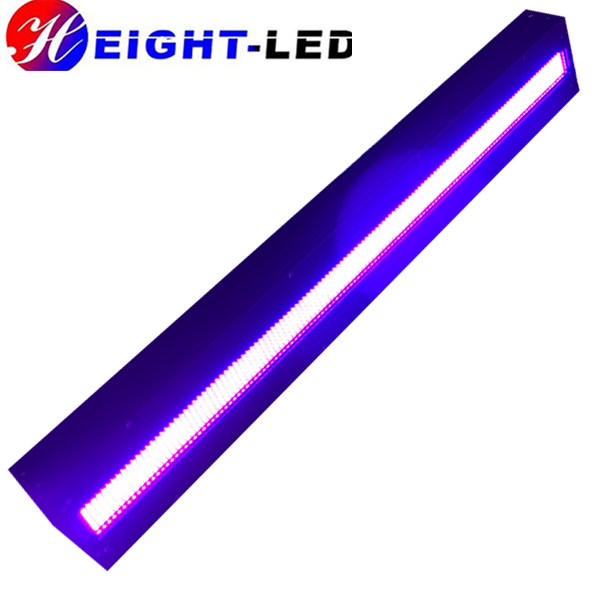

At present, there are three uvled light sources of illumination mode, one of which is a uvled surface light source.

The UVLED surface light source is a semiconductor light-emitting device that directly generates ultraviolet light,

and is a light source that integrates a high-power LED chip having an emission wavelength of 200 nm to 450 nm to

form a wavelength of a wavelength of 200 nm to 450 nm in a certain ratio.

UVLED surface light source has long service life, cold light source, no radiant heat, high energy, uniform illumination,

instant on and off to improve production efficiency and save energy and cost. It does not contain harmful substances and

is safer than traditional light sources. More environmentally friendly.

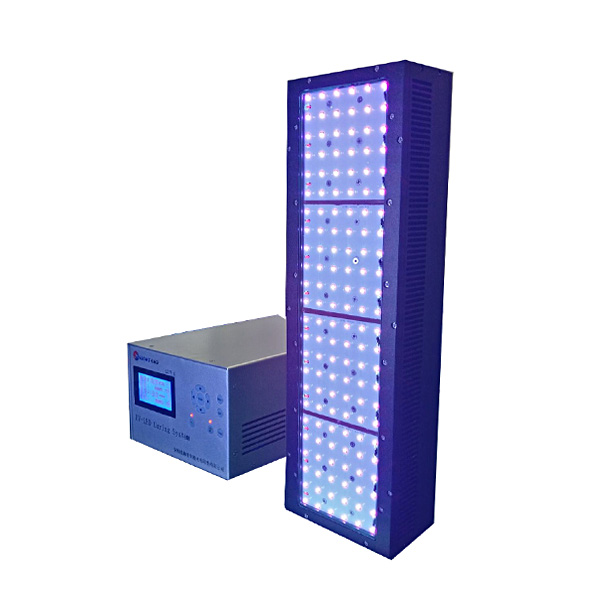

UVLED surface light source is mainly used:

Sensor manufacturing (gas sensors, photoelectric sensors, fiber optic sensors, photoelectric encoders, etc.)

Computer hard disk head assembly (package of head and head, gold wire fixing, bearing, coil, chip bonding, etc.)

DVD/digital camera (lens, lens stick, circuit board reinforcement)

Component assembly on the mobile phone (camera lens, earpiece, microphone, housing, LCD module, touch screen coating, etc.)

The UV package curing of the laser generator uses motor and component assembly (wire, coil fixing, coil end fixing,

PTC/NTC component bonding, protection transformer core)

Shenzhen Height-led Opto-electronics Technology Co., Ltd. specializes in the production of UVLED light source curing equipment,

UVLED curing equipment, UVLED curing furnace, is a high-tech enterprise integrating R&D, production and sales.