Printing is one of the inventions in China.

With the development of the times, traditional printing can't satisfy people's needs.

In order to solve this problem, UV printing has entered people's field of vision.

The UV printing process has only been developed in recent years.

UV printing is to cure the ink containing photosensitizer on the surface

of the printed matter by UV drying, so that the packaging of our daily

necessities presents a variety of colors and styles.

advantage

1. Environmental protection

UV printing uses UV inks, does not contain volatile substances,

is safer to the environment, and does not harm the health of the operator.

2, more efficient

The UV printing has a fast curing speed and the product is quickly dried,

so that it can immediately enter the next step, reducing the waiting time

between processes and improving efficiency.

3. Wide adaptability of printing materials

UV printing can use not only paper and paperboard, but also a wide variety of substrates,

including low-absorbency or non-absorbent plastics, foils, metals and more.

4, good performance

UV ink adhesion is strong, packaging is safe, and it has excellent friction resistance and folding resistance.

5, high returns

Although the cost of UV ink is relatively high, the price of UV printing products is relatively high.

After increasing the efficiency and increasing the selling price, the cost will be relatively low and

the profit will increase.

Disadvantage

1. Need to add multiple sets of UV curing devices.

2. The storage of UV ink and UV varnish is greatly affected by temperature

and must be kept below 25 °C.

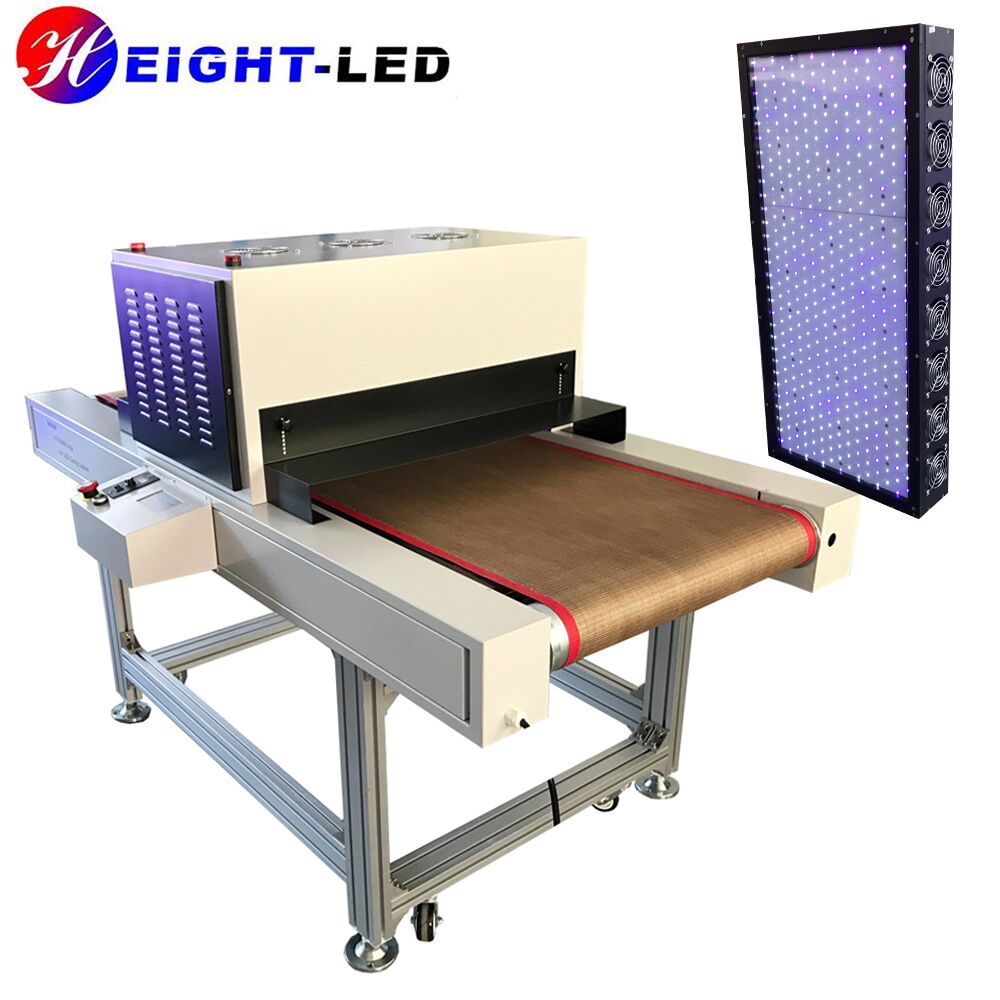

Height-led is a professional UV curing equipment manufacturer, integrating R&D,

production and sales, and product quality assurance.

There are light sources and curing machines for UV printing.