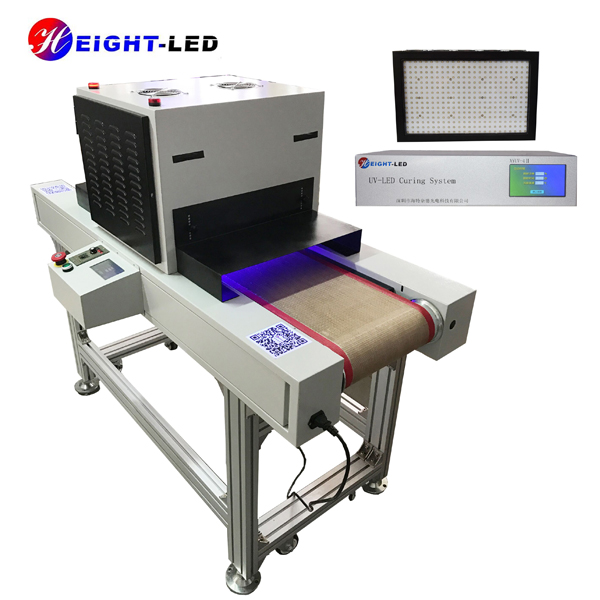

Height-led is a professional UVLED curing equipment manufacturer,

integrating R&D, production and sales, and product quality

assurance.Let Xiaobian introduce the advantages of Heitner UV curing equipment.

First, the environmental protection generally mercury lamp tube contains mercury,

waste lamp treatment and transportation is not convenient,

and the environment is more polluted; UVLED light curing machine

uses chips and UVLED lamp beads to emit light,

no other impurities and harmful substances,

the environment Will not cause pollution.

Second, the safety light curing equipment emits pure

ultraviolet light, no heat radiation and infrared rays,

and the surface temperature rise of the irradiated product is generally

below 5 ° C; the ordinary mercury lamp emits a large amount of infrared light,

and the temperature is high, and generally the irradiated The surface of the

product is raised by 60-90 °c, which causes the positioning of the product

to shift and affect the product yield.

Third, low energy consumption and long life The light curing machine energy

consumption is only 20% of mercury lamps, and the luminous efficiency is as high

as 10 times that of mercury lamps. Ordinary mercury lamps require continuous

lighting and excessive power consumption. The uvled mode consumes power only

when it is illuminated, while the power is not consumed during standby.

Save more power. Long service life, can reach more than 20,000 hours.

4. Open and close. It can be turned on at any time according to the need,

without preheating, which can effectively improve production efficiency.

5. Wide applicability, UV curing machine can meet the requirements of heat

sensitive and high precision bonding process of plastic substrate, lens bonding

and electronic products, fiber optic cable.

Sixth, Height-led has a professional R & D production team,

can be customized to effectively solve your problems.