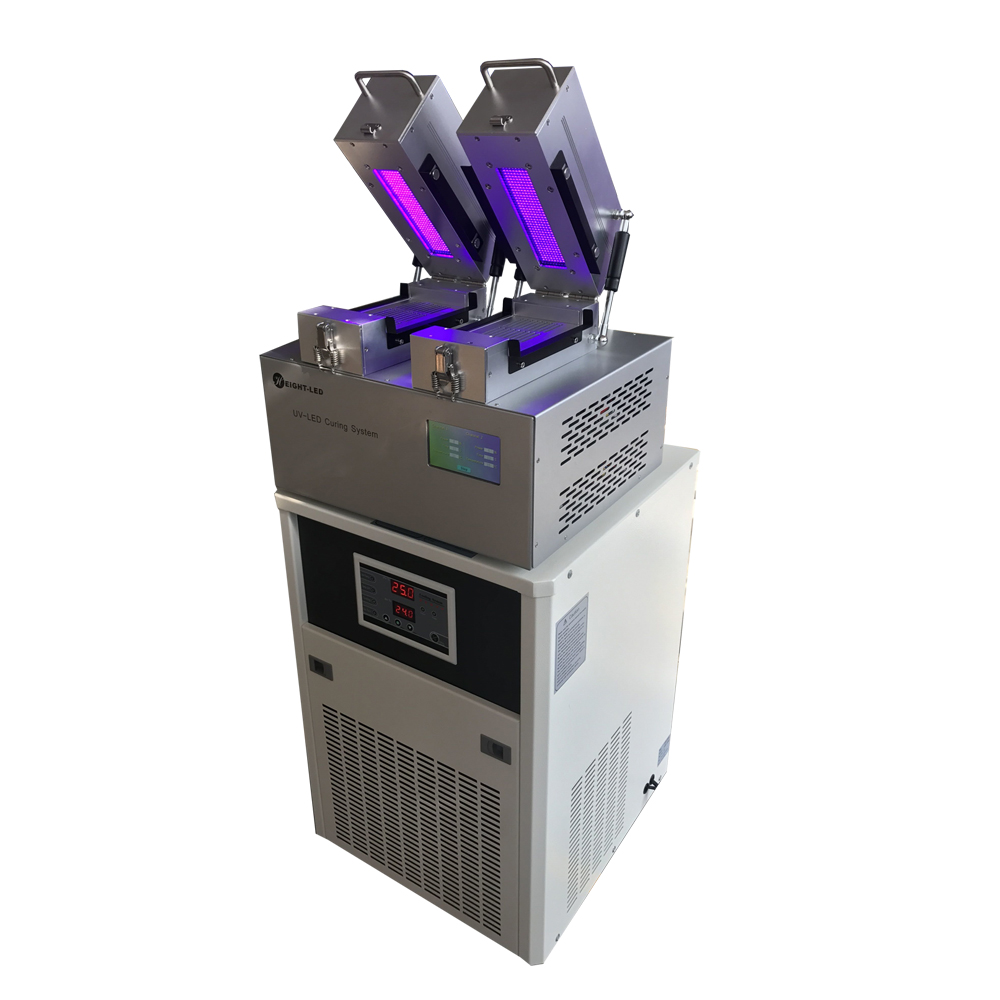

Today, UV printing is used more and more in the printing industry,

and many fine notebooks or magazines use UV printing.

UV printing is to cure the ink containing photosensitizer

on the surface of the printed matter by UV drying, so as

to form a bright film with artistic effect on the surface of

the printed matter; the surface is convex and elastic,

which can better highlight the graphic part. The subtle level

and graphic outline can be used to attract customers' attention.

There may be problems with ink drawing during UV printing,

which is why we need to figure out why. Next, let me introduce

the reason for pulling ink.

1.Ink emulsification: When printing aluminum foil paper with UV offset ink,

when printing, sometimes it is found that the periphery of the printing dot

is a little hairy, the picture is not clear; this is mainly caused by the imbalance of ink.

Compared with oil-based inks, UV inks supply slower UV offset inks,

while the printing ink layer is thinner, resulting in more serious emulsification

of the ink. The emulsified ink will accumulate on the inking roller and remain

on the layout and blanket. The picture is unclear.

2. Insufficient ink adhesion: Because the permeability of the film, synthetic paper,

metal, plastic and other substrates is very poor, the adsorption force on the ink is not enough.

Even after UV curing, the adhesion of the ink is very poor, and the printing quality is not high.

In order to improve the adhesion of the ink,

It is usually done by surface treatment of the material.

3. When the ink is cured and dried incompletely, in order to improve the color

saturation of the UV print, the printing pressure is large, the ink layer is thick,

and the dot gain is serious, which will increase the difficulty of ink curing.

In order to ensure color reproduction, it can only maintain a large Printing pressure.